Why CO₂ Absorbents Are Not Interchangeable: SpiraLithCa®

C02 absorbents have traditionally been viewed as interchangeable components of the anesthetic breathing circuit. If a canister fits the machine and removes co2 its is often assumed to perform just as well as any other. However, clinical evidence and modern anesthesia practices suggest this assumption overlooks meaningful differences in safety, performance, and consistency.

While all CO₂ absorbents serve the same purpose, their formulation and physical design significantly influence their performance. Studies comparing calcium hydroxide-based absorbents have shown a wide variability in absorption efficiency, reaction consistency, and byproduct formation. These differences can affect the reliability with which CO₂ is removed during anaesthesia.¹

Traditional granular CO₂ absorbents have inherent limitations. Channeling allows gas to follow the path of least resistance, leaving large portions of the absorbent unused. Dust generation is another drawback of granular absorbents and can lead to failed anesthesia machine checks, increased machine maintenance, and equipment downtime. Additionally, traditional granular absorbents can generate other harmful byproducts such as carbon monoxide and formaldehyde.

Moving Beyond the Commodity Mindset

Advances in absorbent technology have led to alternatives that address the challenges associated with granular absorbents. SpiraLithCa® utilizes Solid Absorbent Technology™ that is cleaner and safer for patients and anesthesia machines. SpiraLithCa® is engineered with fixed gas pathways that eliminate channeling and ensure uniform use of all the absorbent material.

SpiraLithCa® is compatible with Dräger, GE, and Mindray anesthesia workstations and can integrate seamlessly into clinicians’ current workflow.

By delivering predictable performance, eliminating dust, and supporting low-flow anesthesia, SpiraLithcCa® represents a shift away from treating CO₂ absorbents like commodities. As expectations for patient safety, comfort, and consistency rise, absorbent selection deserves the same level of consideration as other components of the anesthesia circuit.

SpiraLithCa® Highlights

- No dust and no channeling

- Predictable, repeatable performance

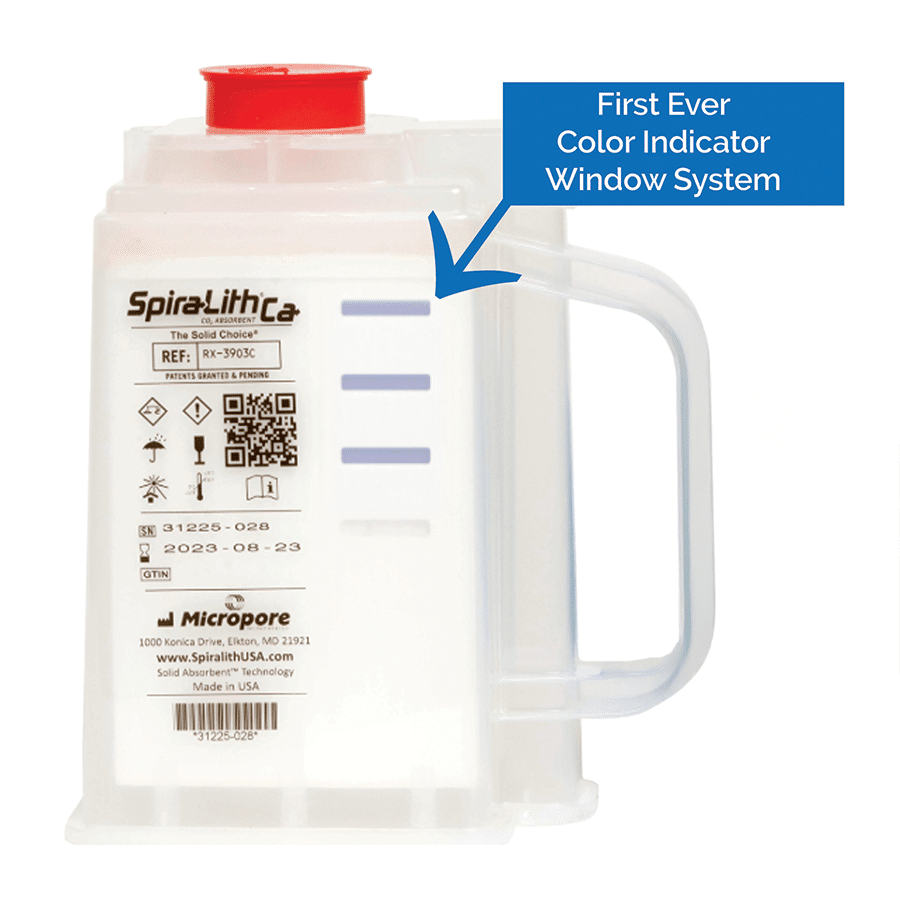

- Clear and reliable color change for absorbent life

- Safe for all flow rates, including low-flow anesthesia

- Enhanced safety and reduced maintenance

- No production of Compound A, carbon monoxide, or formaldehyde

- Cost-effective with superior duration

- Non-hazardous disposal with reduced environmental impact

- Made in the USA

For more information or an evaluation of SpiraLithCa® Absorbent contact your local MED Alliance Group sales representative, call 888-891-1200 or email us.

Reference:

¹Eger, Edmond I., II, et al. “Carbon Monoxide Production by Desiccated Carbon Dioxide Absorbents during Anesthesia.” Anesthesia & Analgesia, vol. 99, no. 2, 2004, pp. 573–580. doi:10.1213/01.ANE.0000132311.83622.41.

MED Alliance Group is a medical device distributor that has been dedicated to meeting the needs of our clinical customers and manufacturing partners since 1998. We specialize in the sales, marketing, importation, logistics and distribution of innovative, high-quality and cost-effective products found in anesthesia and respiratory, blood and transfusion therapy, EMS and emergency room, interventional radiology and cath lab, iv and vascular, as well as NICU and PICU.

Please follow us on LinkedIn, Facebook and Twitter for MED Alliance product updates.