Eliminate the risks of granular absorbents during low-flow anesthesia

Although low-flow safe CO2 granular absorbents mitigate toxic byproducts during anesthesia, they raise concerns about hospital equipment, overall costs and environmental impact.

Channeling in Granular Absorbents

Channeling in granular absorbents occurs when exhaled gas takes the path of least resistance through the granules, bypassing the reactive material. Channeling can be caused by random settling of the granular absorbent during manufacturing, shipping or use. As a result, gas may flow through various paths in the absorbent bed, along the smooth canister wall or settle within the canister’s core.

Channeling leads to highly variable performance duration, increased canister usage and costs, as well as significant unreacted absorbent waste that ends up in landfills. Additionally, channeling can pose safety concerns when the lack of a visible color change encourages continued use of the product, even when granules along the path of least resistance are completely expired, potentially degrading volatile anesthetics to toxic byproducts.

Color Changing in Granular Absorbents

The color change in granular absorbents is often unreliable and meaningless due to random flow, channeling and the granules’ tendency for color reversion during periods of non-use. What is visible on the outside of the canister does not reflect what is happening inside. In fact, it is not uncommon for exhausted canisters to show little or no visible color change, which can make them confusing and potentially dangerous, as desiccated canisters are known to produce toxins. One method to mitigate this risk is more frequent canister changeouts; however, this increases canister usage, which affects cost and environmental disposal concerns.

Dusting from Granular Absorbents

Dust-related problems are a very serious issue associated with all granular absorbents and are well known to cause complications that negatively impact operating room efficiency. In addition to exposing patients, providers and biomedical personnel to chemical dusting, the presence of dust also leads to an increased need for replacement parts, such as sensors, o-rings and valves. Buildup of dust is also well known to cause machine pressure test failures and potentially operating room downtime, further driving up hospital costs.

Environmental Footprint from Granular Absorbents

Volatile, unreacted anesthetics are potent greenhouse gases that harm the environment by depleting the ozone layer and contributing to global warming. The gases also remain in the atmosphere far longer than carbon dioxide. Used absorbent canisters contain residual amounts of these volatile anesthetics that escape into the atmosphere from landfills. Additional environmental concerns arise from unreacted chemical absorbents and their respective plastic housings. The increased use of absorbents to address issues such as channeling and color change further exacerbates their environmental impact, and their disposal is often subject to regulations and can be costly.

The Solid Choice: SpiraLithCa® Solid Absorbent Technology™

No Channeling. No Dusting. No Duration Penalty.

SpiraLithCa from Micropore utilizes revolutionary Solid Absorbent Technology to solve all the problems associated with granular absorbents used during the administration of anesthesia. SpiraLithCa is comprised of absorbent powders bound together by a polymer matrix to form a solid absorbent sheet. It is specifically engineered to have uniform air passages that eliminate channeling and ensure uniform cartridge use and longer duration. Clinicians can now take advantage of low-flow anesthesia and its benefits without consequence.

Efficient Absorption

- No channeling of gases – all absorbent is exposed to exhaled gas

- Maximum surface area for reaction with carbon dioxide in exhaled gases

- Highest absorption efficiency of any absorbent

Reliable Duration Performance

- Reliable and repeatable performance for every cartridge resulting from uniform air passages

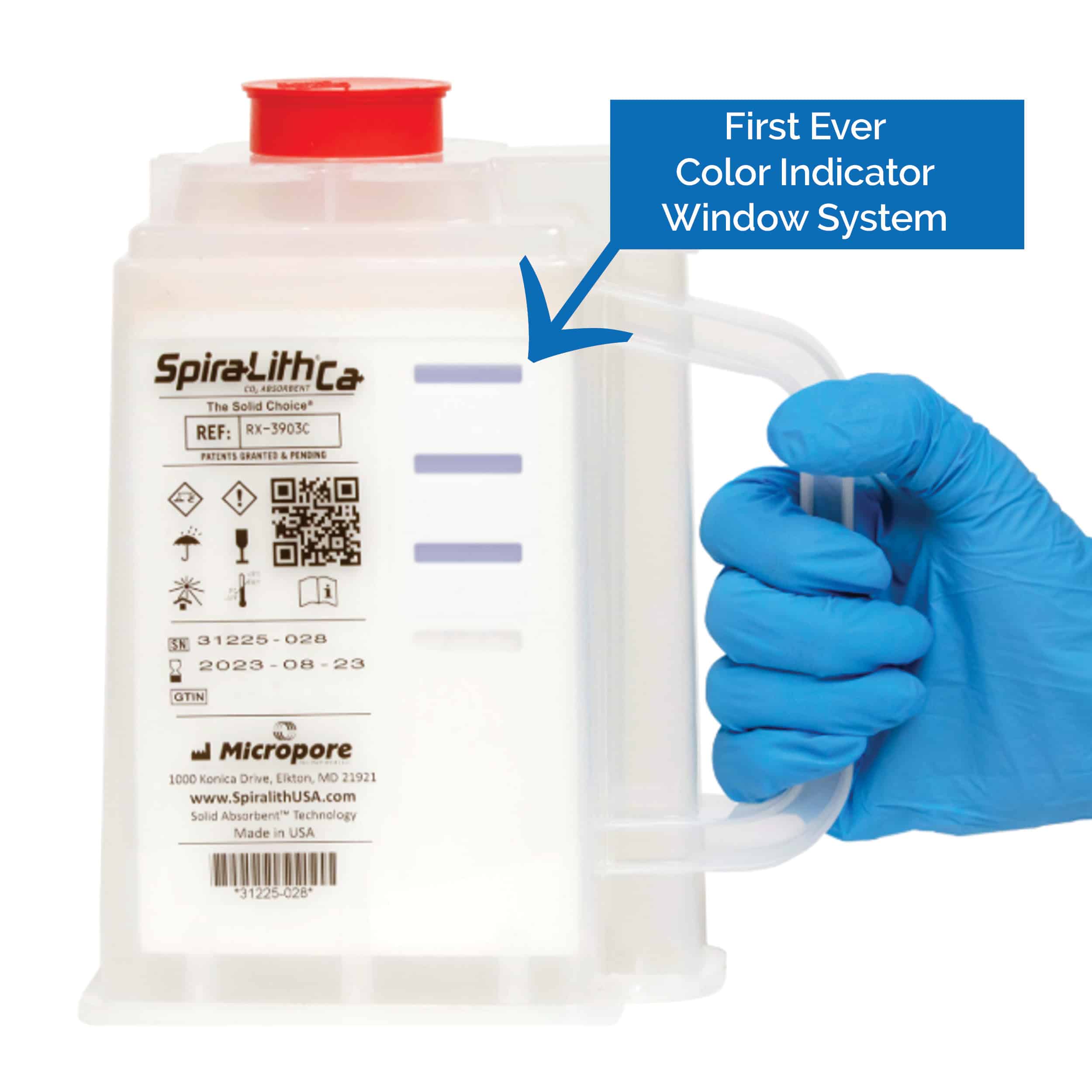

- The unique color indicator window system is the only indicator system that can approximate remaining duration and is the easiest to interpret.

- Reliably shows progressive utilization and remaining absorbent; lets you know when to change out the cartridge

- Bold, fade-resistant color

- Color will not revert

Enhanced Safety

- No caustic dust

- Easily handled with no risk to patients or staff

- Does not contaminate ventilation equipment with dust

- Reduced pressure test failures and biomedical costs

- Low-flow formulation

- No production of Compound A or Carbon Monoxide

Reduced Environmental Impact

- Promotes safe use of reduced fresh gas flow rates

- Less absorbent material is used

- Lower pH due to low-flow chemistry

- Reduction of unreacted absorbent in the waste stream

- No restrictions on disposal

For more information or an evaluation of SpiraLithCa® Absorbent contact your local MED Alliance Group sales representative, call 888-891-1200 or email us.

MED Alliance Group is a medical device distributor that has been dedicated to meeting the needs of our clinical customers and manufacturing partners since 1998. We specialize in the sales, marketing, importation, logistics and distribution of innovative, high-quality and cost-effective products found in anesthesia and respiratory, blood and transfusion therapy, EMS and emergency room, interventional radiology and cath lab, iv and vascular, as well as NICU and PICU.

Please follow us on LinkedIn, Facebook and Twitter for MED Alliance product updates.